In the pharmaceutical industry, special requirements and strictures usually apply with regard to product tracking. These include:

- Increasing quantities of small products, so-called micro batches, require a highly flexible and at the same time efficient and reliable reading process

- Optimisation of productivity and increase in such micro-batches, in particular processes such as set-up times, format changes and cleaning

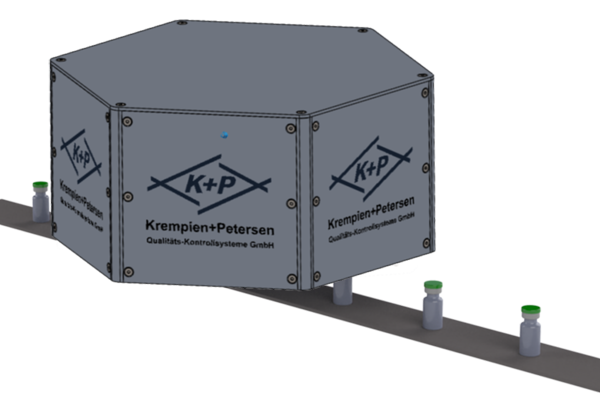

Code reading unit 360°

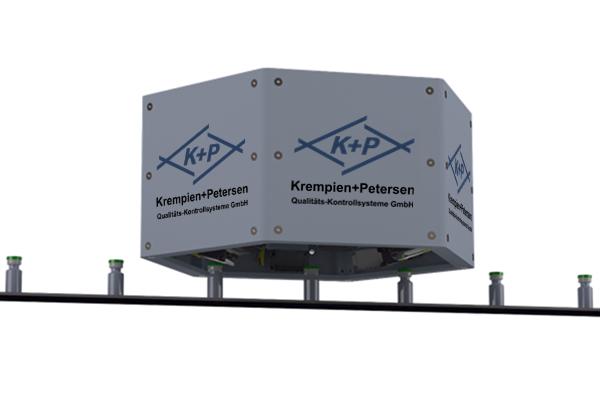

6 integrated DataMan reader

Our specific market-orientated system solution Code Reading Unit 360° (CRU-360°) has the following highlights:

- Reliable reading of codes on round containers such as vials, ampoules, bottles, cans or tubes

- Maximum production efficiency / output of up to 600 products per minute

- No interruption of the production facilities

- Rugged housing

- Easy integration into existing control systems, e.g. Profibus, CAN bus, Interbus, Profinet, EIP, digital I/O etc.

- External light - absolutely independent of external light influences

- Alignment-neutral code read-back, verification of GS1 conformity, in-line verification in accordance with ISO 15415, 16022, AIM DPM or IAQG

- Out-of-the-Box System

- Plug & Play

- Full IQ / OQ Documentation

- Optional: Visualisation and format management via our software KUPvision

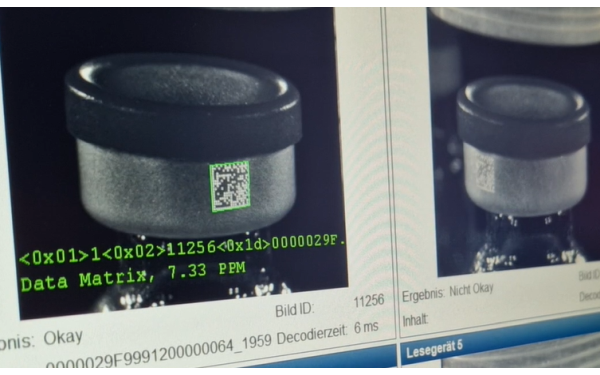

DMC reading 360°

Camera image from DM280 with reading result

Technical data CRU-360°

- Fully integrated COGNEX DataMan 280

- Code size min. 3 x 3 mm, max. 8 x 8 mm

- Output up to 600 products per minute

- Format range min. Ø 8 mm, max. Ø 30 mm

- Cap height from 4 mm to 8 mm

- Data output via TCP/IP, read content as string or "NOREAD", integrated Siemens S7-1200

- Positioning accuracy max. ± 2 mm from center position

- Trigger light sensor, signal light, visualization, format management, audit trail

- Power supply 24 V

- Net weight 7 kg